Re-circulating Aquaculture System (RAS)

RAS Technology is a popular environment-friendly and highly productive LAND-BASED indoor fish farming system which is fully automated under controlled environment and disease-free industrial-scale production. The technology is based on the use of various mechanical & biological instruments operated through SCADA system and the method can be used for any species grown in aquaculture such as whitefish, shrimps, catfish, etc. Re-circulating technology is used in large scale fish farming and is proven to be very highly resourceful in the developed countries for the last 30 to 40 years due to use of efficient land, less labor-intensive as well as its healthy fish concept.

In comparison to the traditional cultivation of fish, RAS can yield magnified volumes of healthy fish in a scientific way. In traditional cultivation, we can get 5 tons of whitefish in 1-hectare land area, whereas, in RAS systems we can get 1300 tons production in the same piece of land. i.e. only 0.34% (ZERO POINT THREE FOUR PERCENT) of land required as compared to traditional cultivation.

A brief description of RAS Technology

In a recirculating aquaculture system the water is purified and reused continuously. A recirculating aquaculture system is an almost completely closed circuit. The produced waste products; solid waste, ammonium and CO2, are either removed or converted into non-toxic products by the system automatically. The purified water is subsequently saturated with oxygen and returned to the fish tanks. By recirculating the culture water, the water and energy requirements are limited to an absolute minimum. The non-degradable waste products are removed and evaporated water are also replaced. Recirculating systems are capable of reusing 90% or more of the culture water. To ensure good water purification, recirculating systems consist of a number of components with specific functions.

Recirculating aquaculture system, or RAS, provide a constant and controlled environment for the fishes, allowing for optimal and fully manageable production under completely disease controlled system where biosecurity is ensured.

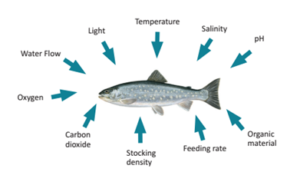

Actually, the technology deals with water parameters to maintain the quality of water in a fully organic way. All the natural parameters of water in the tanks are controlled through sensors and adjusters in SCADA software conducive to fish biology ensuring the unique growth and well-being of fish without using of any sort of chemical.

RAS water treatment processes

A series of treatment processes are utilized to maintain water quality in intensive fish farming operations. These steps are often done in order or sometimes in tandem. After leaving the vessel holding fish the water is first treated for solids before entering a bio filter to convert ammonia, next degassing and oxygenation occur, often followed by heating/cooling and sterilization. Each of these processes can be completed by using a variety of different methods and equipment, but regardless all must take place to ensure a healthy environment that maximizes fish growth and health.

Bio filtration

All RAS relies on bio filtration to convert ammonia (NH4+ and NH3) excreted by the fish into nitrate.[4] Ammonia is a waste product of fish metabolism and high concentrations (>.02 mg/L) are toxic to most finfish. Nitrifying bacteria are chemoautotrophs that convert ammonia into nitrite then nitrate. A bio filter provides a substrate for the bacterial community, which results in thick biofilm growing within the filter. Water is pumped through the filter, and ammonia is utilized by the bacteria for energy. Nitrate is less toxic than ammonia (>100 mg/L), and can be removed by a denitrifying bio filter or by water replacement. Stable environmental conditions and regular maintenance are required to ensure the bio filter is operating efficiently.

Solids removal

In addition to treating the liquid waste excreted by fish the solid waste must also be treated, this is done by concentrating and flushing the solids out of the system. Removing solids reduces bacteria growth, oxygen demand, and the proliferation of disease. The simplest method for removing solids is the creation of settling basin where the relative velocity of the water is slow and particles can settle at the bottom of the tank where they are either flushed out or vacuumed out manually using a siphon. However, this method is not viable for RAS operations where a small footprint is desired. Typical RAS solids removal involves a sand filter or particle filter where solids become lodged and can be periodically back flushed out of the filter.[7] Another common method is the use of a mechanical drum filter where water is run over a rotating drum screen that is periodically cleaned by pressurized spray nozzles, and the resulting slurry is treated or sent down the drain. In order to remove extremely fine particles or colloidal solids a protein ractionators may be used with or without the addition of ozone (O3).

Oxygenation

Re-oxygenating the system water is a crucial part to obtaining high production densities. Fish require oxygen to metabolize food and grow, as do bacteria communities in the bio filter. Dissolved oxygen levels can be increased through two methods aeration and oxygenation. In aeration air is pumped through an air stone or similar device that creates small bubbles in the water column, this results in a high surface area where oxygen can dissolve into the water. In general due to slow gas dissolution rates and the high air pressure needed to create small bubbles this method is considered inefficient and the water is instead oxygenated by pumping in pure oxygen.[8] Various methods are used to ensure that during oxygenation all of the oxygen dissolves into the water column. Careful calculation and consideration must be given to the oxygen demand of a given system, and that demand must be met with either oxygenation or aeration equipment.

pH control

In all RAS pH must be carefully monitored and controlled. The first step of nitrification in the bio filter consumes alkalinity and lowers the pH of the system. Keeping the pH in a suitable range (5.0-9.0 for freshwater systems) is crucial to maintain the health of both the fish and bio filter. pH is typically controlled by the addition of alkalinity in the form of lime (CaCO3) or sodium hydroxide (NaOH). A low pH will lead to high levels of dissolved carbon dioxide (CO2), which can prove toxic to fish. pH can also be controlled by degassingCO2 in a packed column or with an aerator, this is necessary in intensive systems especially where oxygenation instead of aeration is used in tanks to maintain O2 levels.

Temperature control

All fish species have a preferred temperature above and below which that fish will experience negative health effects and eventually death. Warm water species such as Tilapia and Barramundi prefer 24 °C water or warmer, where as cold water species such as trout and salmon prefer water temperature below 16 °C. Temperature also plays an important role in dissolved oxygen (DO) concentrations, with higher water temperatures having lower values for DO saturation. Temperature is controlled through the use of submerged heaters, heat pumps, chillers, and heat exchangers. All four may be used to keep a system operating at the optimal temperature for maximizing fish production.

Degassing

From the pump tank the system water is first pumped to the bio tower. A bio tower consists of polypropylene net filter blocks suited for bio-filtration. On top of the bio tower the water is dispersed over the filter material. The water flows through the filter packs to the bio tower reception tank or directly back into the pump tank. A biofilm of nitrifying bacteria is formed on the surface of the filter packs. A bio tower can also be added to the system to remove dissolved gasses (i.e. CO2) from the water. In that case, we speak of a degassing tower.

Moving Bed Bio Filter

Another biological filter is the moving bed filter. These filters have a high filter capacity with low volume. From the pump tank the water is pumped into the moving bed filter. The moving bed filter consists of a tank with aeration device and is filled with filter beads (many shapes and sizes available). A biofilm of nitrifying bacteria grows on the surface of the beads.

Biosecurity through UV Technology

Disease Outbreaks occur more readily when dealing with the high fish stocking densities typically employed in intensive RAS. Outbreaks can be reduced by operating multiple independent systems with the same building and isolating water to water contact between systems by cleaning equipment and personnel that move between systems.[14] Also the use of a Ultra Violet (UV) or ozone water treatment system reduces the number of free floating virus and bacteria in the system water. These treatment systems reduce the disease loading that occurs on stressed fish and thus reduce the chance of an outbreak.

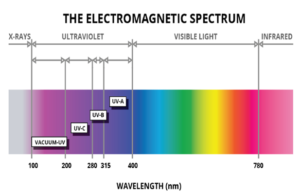

The UV technology is one of the very latest technologies used in intensive RAS to disinfect fluids. The method is based on the natural disinfectant action of the sun’s rays. UV lamps imitate the disinfecting rays of the sun. UV systems produce the same ultraviolet germicidal rays, just thousands of times stronger. No bacteria, viruses, moulds or their spores can survive after this treatment.

The reaction time between the UV irradiation and the organism to be killed is very short and does not create any by-products at all. The water quality, both physical and chemical, remains identical before and after treatment using the UV technique. The UV disinfection can therefore take place at any conceivable and necessary place in a system.

UV-C LIGHT

UV-C light is highly germicidal and has an antiseptic effect. With the use of irradiation of UV-C light to a contaminated surface, or in running water, it is possible to control excessive growth of micro-organisms including bacteria. UV disinfection is a proven method to kill off bacteria, viruses and fungi, but first and foremost to keep the system water clear and free of small particles even at low dosage.

Monitoring and control

Automated systems facilitate to monitor and control every relevant parameter. The system lets regulate the oxygenation of every tank, adjust the pH of the water to optimize the bio filtration process and control converters for pumps and fans. In addition, the system is set up with alarms for important parameters, so that the entire facility can be controlled remotely from the control room.

The advantages of farming in RAS are:

- Fully controlled environment

- Less Labor intensive

- Low water use

- Efficient energy use

- Efficient land usedue to the high stocking density

- Optimal feeding strategy

- Easy grading and harvesting of fish

- Full disease control

- Independence from weather and variable environmental conditions

- High demand in world fish market due to its healthy fish concept

- No dependency on any single individual

First and foremost feature of RAS Technology is that it requires only 0.34% (ZERO POINT THREE FOUR %) of land to produce equal amount of fish i.e. what a traditional pond based Fish Farm on 400 Hectares of land produce in a year, can be produced in a shed of less than 2 Hectares of land using RAS Technology with a Task Force of 25-50 persons.

In traditional cultivation we can get 5 ton whitefish whereas in RAS SYSTEM we can get 1300 ton production and it is a healthy fish farming concept.

It may be mentioned here that the Food and Agriculture Organization (FAO) of the UN has highly recommended for RAS technology in a Report published in the year of 2015.

Please visit the following sites through the links below:

https://www.youtube.com/watch?v=_zRR1bZof-s